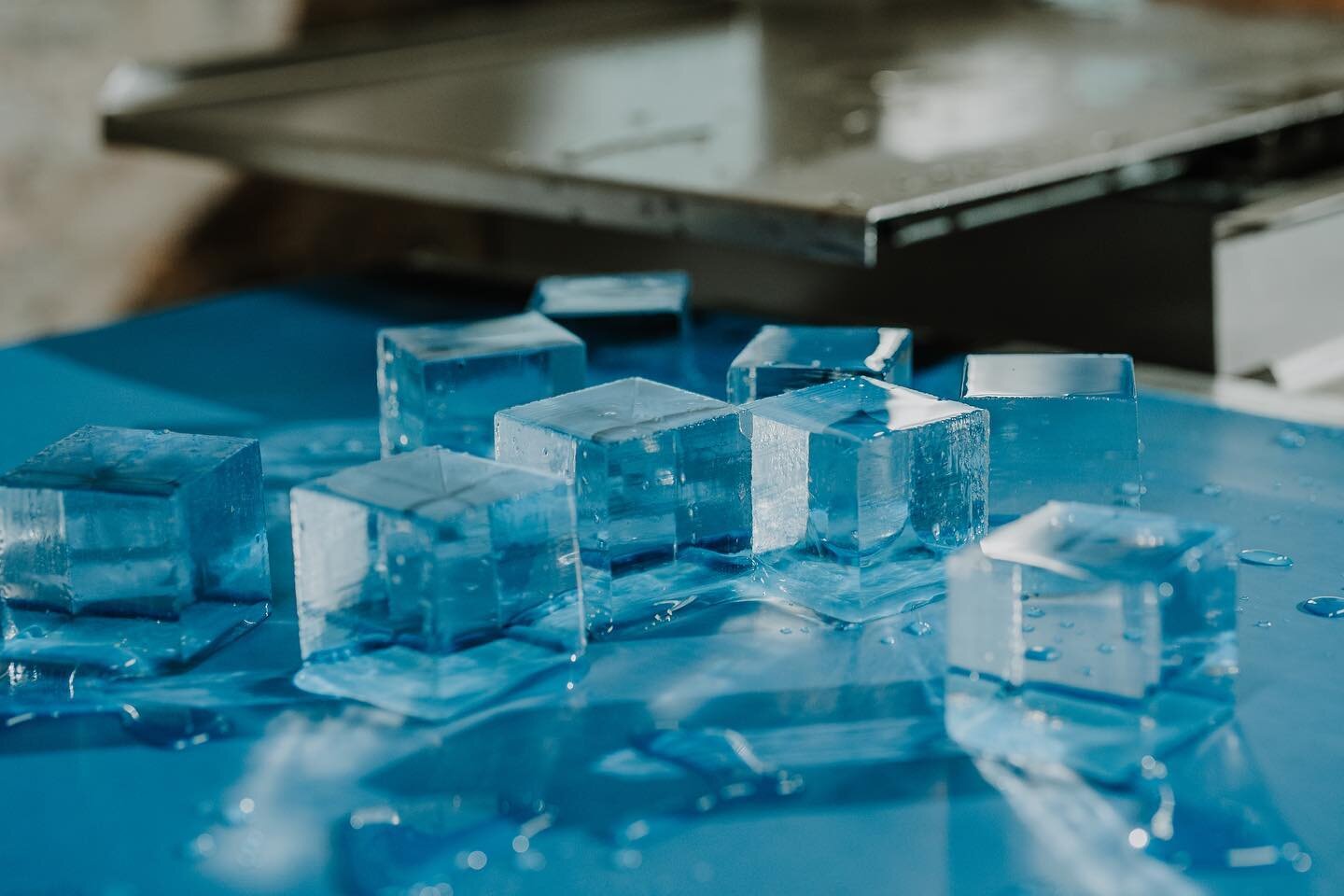

perfecting our process one cube at a time

High quality ice starts with high quality ingredients. We first filter our water to remove as many impurities as possible. The filtered water is then passed into our Clinebell machines, which utilizes a remarkably strong process called directional freezing that removes every last impurity and air bubble, resulting in crystal clear 300lb ice blocks. Using a combination of chain saws and heavy duty band saws, we cut and polish each and every cube by hand.

As a bartender working in St. Louis, I was always disappointed by our lack of access to this sort of ice. I took it upon myself to freeze and cut ice using a knife and hammer for our services, because I truly believed it made a difference. As the popularity of my hand cut ice grew, other bartenders began to ask if I could make ice for them.

featured in:

“Every bar and restaurant we go into, we go and measure the glassware [to] cut a custom size. A lot of other places will just offer two sizes. But we've been in the bar industry for a long time, and we realize that one size doesn't fit all. … If you're a small mom-and-pop, or if you're just opening up and you got all this glassware and then we come in and say, ‘Actually no, to use our ice you have to get a different size cube’ – we just custom fit everything.”

— Jordan Goodman for Sauce Magazine, August 2022

"There was something so satisfying about the process — the nice crack you get when you cut into it, then the look of it when you see it in a cocktail," Goodman says. "You ask for a Sazerac, and you get this beautiful ice cube in it. The presentation and care each step of the way is appreciated by the guest. People could feel the attention going into it and felt like we were taking care of them every step of the way."

— Jordan Goodman for River Front Times, November 2022